view:294

Silicon carbide material

SiC is a single-phase, pressureless sintered SiC ceramic with high purity, fine grain and very low porosity. It has the characteristics of high strength, high temperature resistance, high heat conduction and comprehensive acid and alkali resistance, especially suitable for high temperature, high pressure, strong acid and alkali corrosion, high-speed airflow erosion, particle wear and other harsh working conditions. It can be used as an excellent substitute for graphite, stainless steel, tantalum, Hastelloy metal, fluoroplastics and other traditional materials. It is suitable for extreme environments of high temperature, high pressure, strong corrosion and high wear in chemical, pharmaceutical, metallurgical and other industries.

High thermal conductivity

Thermal conductivity is much higher than other corrosion resistant materials

Use less heat exchange area under the same heat exchange efficiency

Allow smaller heat exchanger size

Greatly reduce space occupation and use cost

Outstanding corrosion resistance

High corrosion resistance, oxidation resistance and erosion resistance

It can resist high concentration sulfuric acid, nitric acid, phosphoric acid, mixed acid, strong base, oxidant, etc

It is the only ceramic material resistant to hydrofluoric acid corrosion

Excellent service life

Excellent thermodynamic properties with high strength and hardness

Under extreme high temperature and high pressure, it still has super wear resistance and permeability resistance

Allow medium to pass at high speed

It can be normally used at 1300 ℃

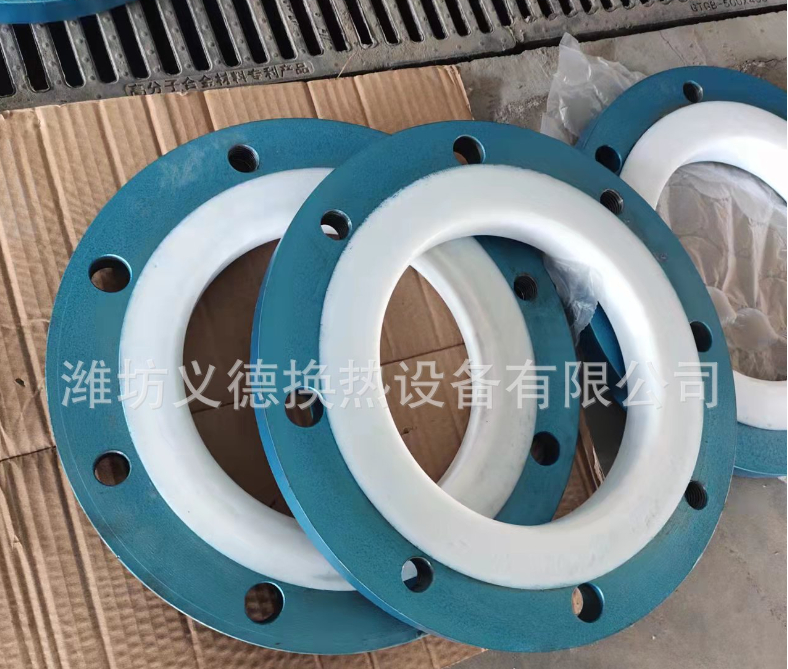

Silicon carbide heat exchanger

It has the high strength, high temperature resistance, high heat conduction and comprehensive acid and alkali corrosion resistance of silicon carbide ceramics, especially suitable for high temperature, high pressure, strong acid and alkali corrosion, high-speed airflow erosion, particle wear and other harsh working conditions. Its excellent heat exchange efficiency can meet the urgent needs of energy conservation, emission reduction and environmental protection.